NonFerrousCast renowned manufacturer of CNC Precision Machined Components, specialize in producing prototypes and new designs in Punjab – Built for Performance, Engineered for Reliability

Precision You Can Trust, From Prototype to Production

CNC Precision Machined Components

High Tolerance Custom Parts | Trusted by Automotive, Aerospace, & Medical Sectors

At the heart of modern manufacturing lies precision — not just in tolerances, but in timing, repeatability, and performance. Our CNC Precision Machined Components are crafted with a clear purpose: to help industries run smoother, longer, and more efficiently. Whether you’re designing high-performance equipment or refining a legacy product, our components are built to fit seamlessly into your workflow.

Why Our CNC Machined Components Stand Out?

Every component we produce is the result of real-world problem solving and attention to detail. Here’s what makes our parts different:

- Tight Tolerances, Every Time: We routinely machine to ±5 microns, ensuring dependable fits and eliminating guesswork in critical assemblies.

- Materials Matched to Application: From aluminum and stainless steel to exotic alloys and engineering plastics, we guide you to the right material for function and cost-efficiency.

- No Surprises – Just Consistency: Thanks to advanced multi-axis CNC machines, we guarantee dimensional repeatability even in high-volume runs.

- Rapid Turnarounds, Without Cutting Corners: Need prototypes fast? We deliver. Need 10,000 parts next month? You’ll get them—on time and within spec.

Industries We Serve – Real Solutions for Real Challenges

Our components aren’t just sitting on shelves—they’re working inside:

- Automotive assemblies – transmission housings, valve bodies, sensor mounts

- Aerospace applications – airframe fittings, custom brackets, thermal shields

- Medical devices – surgical tool parts, housings, implants (ISO-cleanroom compatible)

- Industrial machinery – hydraulic fittings, precision shafts, coupling hubs

- Electronics and defense – enclosures, RF shielding parts, connectors

We understand that each industry comes with unique expectations, and we tailor our machining solutions accordingly.

Custom Machining – Your Specs, Our Expertise

Have a drawing? Or just an idea? NFC collaborate with engineers, designers, and procurement teams to turn complex requirements into real-world components. Every detail matters —material selection, GD&T standards, surface finish, packaging. NFC don’t just ask for a spec sheet — we ask how the part works.

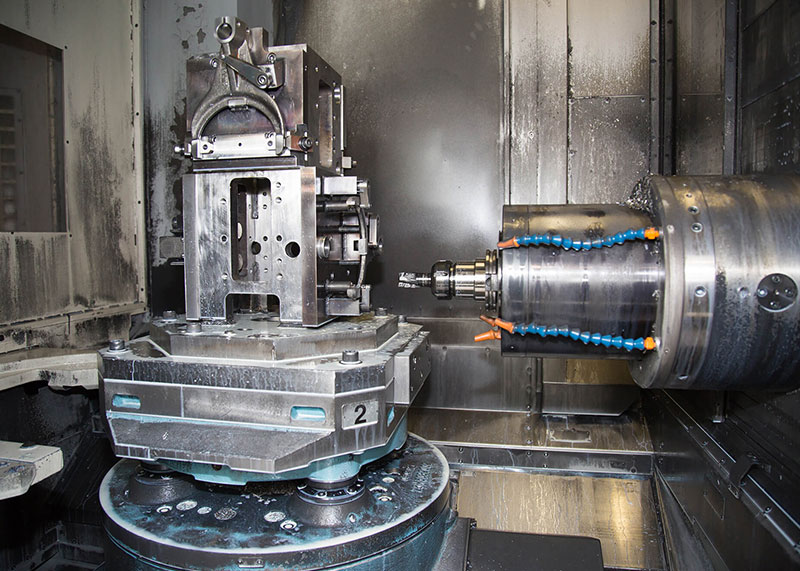

NonFerrousCast is a renowned manufacturer of CNC Precision Machined Components. We specialize in producing both short- and long-term production runs, as well as prototypes and new designs. Our expertise lies in manufacturing complex and precision parts and assemblies with tight tolerances.

At Nonferrouscast, we have a state-of-the-art in-house facility equipped with a complete range of highly precise CNC – VMC – HMC machineries. Our machines range from 7 Axis machining down to 2 Axis, with rotary tables and twin pallets for handling multifaceted machining jobs. These machines are specifically designed for high precision machining to meet our customers’ demands for tight and highly precise tolerances.

Our CNC turning centers have a machining capacity of up to 350 MM diameter, while our CNC vertical machining centers can handle prismatic components up to 800mm * 500mm. We also have horizontal machining centers equipped with 4-axis rotary tables, allowing for multiple axis machining in a single setup. Additionally, we have a twin pallet horizontal machining center that can handle a variety of multifaceted machining jobs.

We take pride in our finishing process, ensuring that every component meets the highest standards of quality and precision.

Simply upload your technical drawing or send it via email with details about the product you need, including the preferred material and production process. Our team will review your specifications and provide a tailored, accurate quote — usually within a few hours.

Once you’re happy with the quote, placing an order is quick and easy. Just confirm the details, and we’ll guide you through the rest. We’ll ensure everything matches your drawing before we begin production.

We understand time matters. As soon as your order is finalized, our team gets to work to deliver your product on time. With a streamlined process and strong logistics support, we make sure your parts reach you fast—without compromising on quality.